Welders4Life - Software Tutorial

W4L APPs - Foreword

Welcome to Welders4Life, our applications are designed to provide weld stress calculations, welding time estimations, and CO2 emissions calculations to assist in your welding projects.

We value feedback from industry users and encourage you to share your suggestions and comments with us via email. It’s important to note that Welders4Life is not an engineering standard or design code but rather a set of recommendations based on sound engineering practices, experience, and other technical rules.

We strongly advise our users to follow specific engineering requirements deemed necessary for safe application, design, and manufacturing of welded joints. Our team is committed to providing high-quality service and support to ensure the success of your welding projects.

Why to use W4L Apps ?

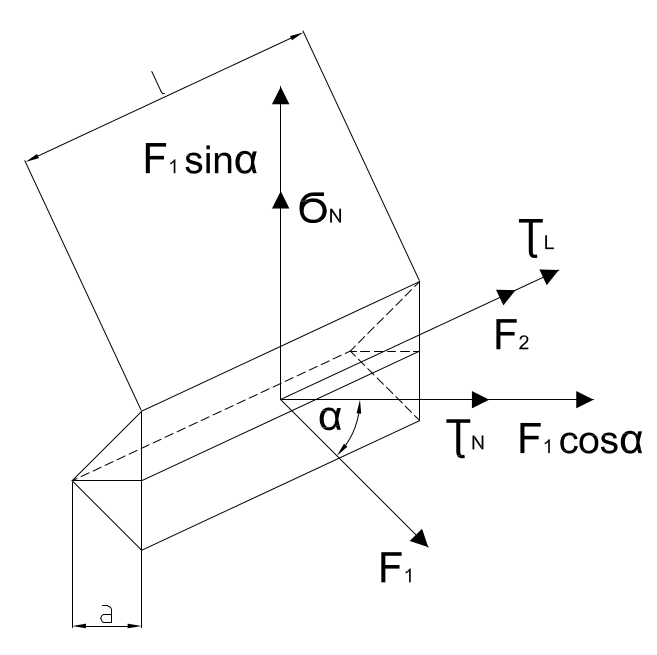

Calculating weld stress is an essential first step in optimizing weld joints. Designers typically have a choice between two methods when calculating fillet welds: the simplified and the directional method.

While there is no specific guidance on which method to use, practical considerations often lead to the use of simplified methods. However, the directional method may be necessary due to the complexity of fillet weld joints and the need for load vector decomposition.

Performing the directional method manually can be time-consuming, as it involves resolving forces and moments acting on the fillet weld into components parallel and transverse to the plane of the weld throat. This results in uniformly distributed normal stresses and shear stresses.

It’s important to note that selecting the appropriate method for calculating weld stress is crucial for the safety and reliability of the welded joint. Our website offers resources and tools to help you make informed decisions when optimizing your weld joints. If you have any questions or suggestions, please don’t hesitate to reach out to us.

While the directional method for calculating fillet weld stress may be time-consuming, it’s often the most beneficial choice when considering optimization of structure, production, and economical factors.

At Welders4Life, we understand the importance of selecting the appropriate method for calculating weld stress, which is why we’ve chosen the directional method as the most suitable for our applications. Despite its complexity, this method provides a more accurate representation of the stresses present in the weld joint and allows for more informed decisions when optimizing welds for safety, reliability, and cost-effectiveness.

We’re dedicated to providing high-quality resources and tools to assist in your welding projects, and we’re committed to continuously improving our web service to meet your needs.

How to use W4L Apps ?

Our Welders4Life applications are designed to be user-friendly and require only basic knowledge related to weld joint design. They’re suitable for engineers, architects, project managers, and anyone else who needs to evaluate stresses for specific fillet and butt weld joints, as well as welding time and CO2 emissions.

The applications provide an interactive display via a user interface, making it easy to interpret and analyze results. Additionally, results can be downloaded as a standalone PDF report, providing a convenient way to save and share your findings.

Weld Stress App :

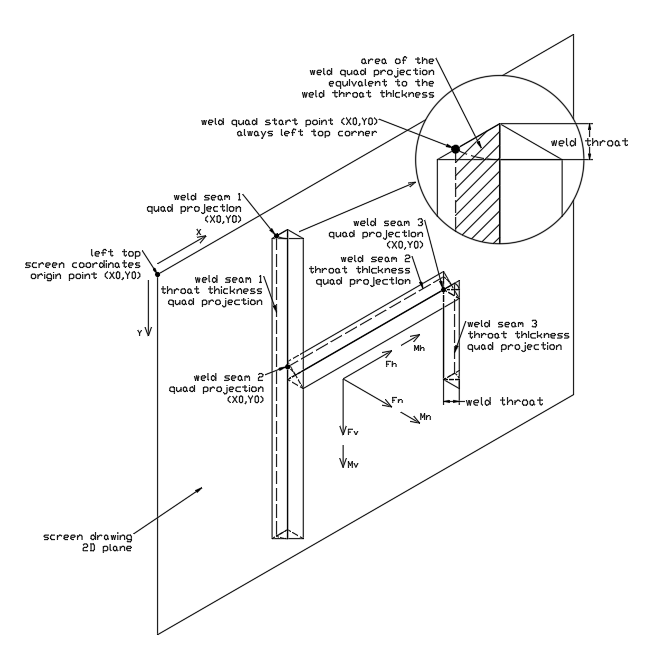

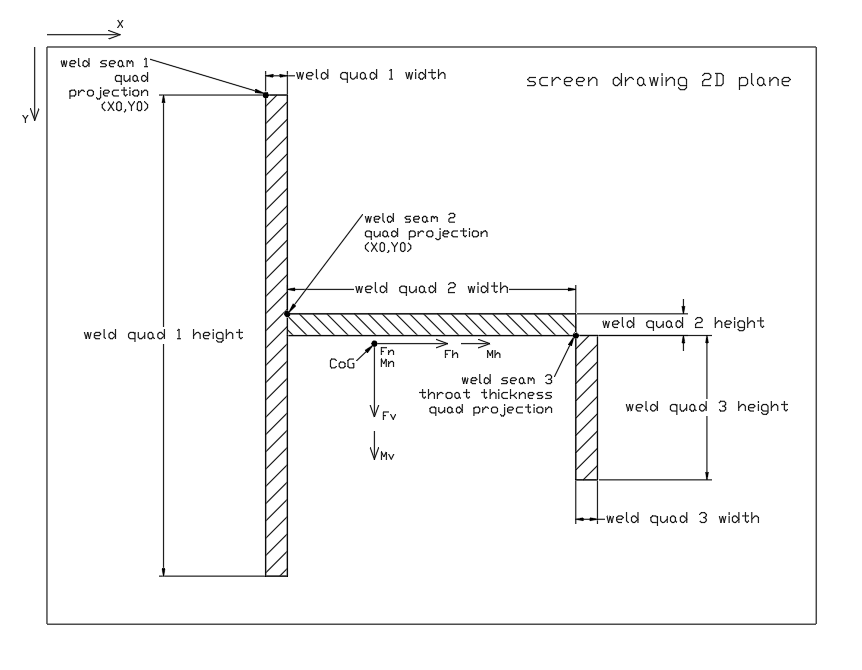

To evaluate the results of weld stress calculations, it’s necessary to create a quad projection based on the width, height, and start coordinates, and add it to the drawing. Additionally, the user must fill in the fields related to the welding methods and geometry.

To assist with this process, we provide an example with explanations of the weld geometry for the user interface input. The pictures below illustrate the necessary steps and provide a clear understanding of how to input the required information.

It’s important to note that the weld stress results provided by our Welders4Life software are informative and should be used as a starting point for further analysis. The results are based on the created geometry and load input, but they must be analyzed further with respect to specific engineering requirements.

We understand that every welding project is unique, and there may be additional factors that need to be considered when evaluating weld stress. Our software is designed to provide a solid foundation for your analysis, but it’s important to apply engineering judgment and expertise to ensure the safety and reliability of your welded joints.

Welding Time and C02 App :

To calculate the welding time and CO2 emissions, simply fill out the user interface form with the requested welding details, process, and geometry. Our software will use average factors to provide an estimate of the welding time and CO2 emissions.

However, it’s important to note that the results provided are based on average factors and do not include any safety margins. If you require calculations based on specific factors, please contact Welders4Life for a customized solution.